Comprising of patented fire-resistant formula, outer thermal insulation surface of Fiberflex is made of fire-resistant material. It can effectively isolate the flame and heat and protect fire retardant elastomeric insulation so that the fire-proofing performance of the entire composite insulation can be significantly improved and better fire safety requirement can be fulfilled. The entire composite insulation was certified by FM approvals, it can be widely used in various civil, commercial and high-rise buildings.

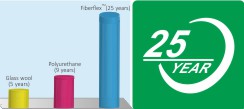

Fiberflex comprises of fire-resistant outer insulation surface and high fire-proofing elastomeric insulation. Double insulation effect improves thermal resistance by 10%. Meanwhile, the integrated composite insulation has infinite moisture resistance and the thermal insulation layer has lower surface heat transfer coefficient, both of which present better thermal insulation performance.

General type of T140 perfectly combines the class A non-combustible material with elastomeric thermal insulation layer. In addition of S142 fireproof layer, fireproof performance of the composite insulation materials is further improved. It is the best fire performance elastomeric composite thermal insulation worldwide.

Hundreds of professional materials can be chosen to produce composite insulation material, which can meet the special engineering requirements such as mildew & fungi proofing, antistatic performance, corrosion protection, UV protection, acid & alkali proofing, water & oil proofing etc. It's the composite insulation material with most complete protection function in the market.

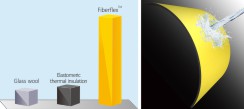

General type T130 elastomeric composite thermal insulation material has lower surface exothermic coefficient and infinite moisture resistance factor and gets better insulation performance. Besides, Special type S231 coating will be covered on the surface of T034 that will achieve double insulation effect.

All the material could be installed in one time and installation time will be shorter. Compared with traditional installation process (iron protection layer + color coating twice), it will save around 30% of the installation time.

Professional type S341, whose surface layer is porous state and has the good permeability based on "lotus effect", can prevent condensation positively and has more powerful condensation prevention function.

.jpg)

Compared with traditional solution (Normal insulation material + external thermal insulation layer + color pigment), composite insulation material could finish the installation in one time. It not only saves the labor cost, but also saves the iron sheet cost while reducing two working processes (Iron sheet installation and color coating process). Total construction cost will be reduced around 10-20%.